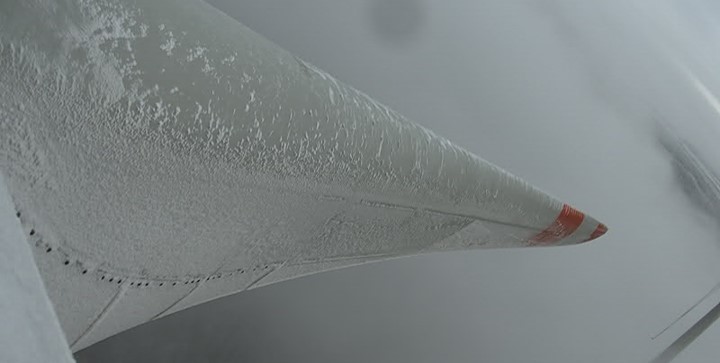

To remove and prevent icing on wind turbine blades (Figure 1), blade heating systems are of central importance. However, blade heating systems have a limited efficiency, which depends on external conditions (including temperature and wind speed). To get the most out of blade heating systems, it is important to operate them in a way that maximizes production while ensuring safe operation. So far, many wind turbines are de-iced based on trivial criteria (predefined de-icing time based on icing criteria) and with fixed parameters (constant de-icing duration and predefined de-icing power).

Figure 1: Iced rotor blades

Therefore, there is considerable potential to use blade heating systems more efficiently if they are controlled based on weather forecasts and depending on external conditions, as well as based on site-specific knowledge from previous winters. For this purpose, wind turbine data and especially data from previous blade heating events need to be analyzed comprehensively. This requires an integrated analysis taking into account the heating energy invested, possible production losses due to forced stops during heating, and the time evolution of production losses due to disturbed blade aerodynamics caused by icing.

The project “Smart Operation of Wind Power Plants in Cold Climate” (SOPWICO) is funded by the vgbe Research Foundation, as well as eight VGBE partners (BKW, CGNEE, EVN, fortum, steag, SWM, Vattenfall, Verbund) to develop an algorithm to determine the best de-icing time based on weather and icing forecasts as well as current wind turbine measurement data. Four of the VGBE partners (BKW, CGNEE, Vattenfall, Verbund) not only support the project financially, but also provide turbine data from their respective wind farms (Figure 2).

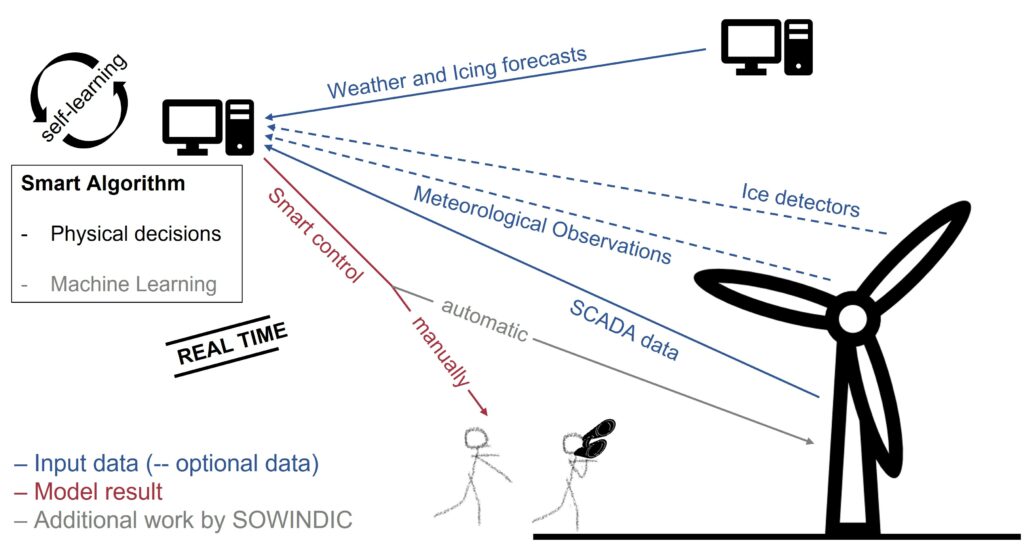

The data are of central importance for the project to develop and test the algorithm. Therefore, data from four wind farms in Europe will be analyzed as part of SOPWICO. The results of the comprehensive analysis will be combined with site-specific conditions and weather forecasts. In order to generate an optimal prediction of the best de-icing time, current meteorological conditions and the status of the wind turbine as well as weather and icing forecasts for the turbine site are taken into account. Based on the external conditions and the operating concept of the wind turbine, the best de-icing time, for which the lowest energy losses are expected, is determined based on numerous scenarios (Figure 3).

The SOPWICO project is also a partner project of the “Smart Operation of Wind Turbines under Icing Conditions” (SOWINDIC) project – a project funded and supported by the Austrian Research Promotion Agency (FFG). SOWINDIC, with a similar project goal to SOPWICO, is developing an algorithm based on physical decisions in parallel with the development of an algorithm based on machine learning methods. In addition, SOWINDIC is developing a solution for the (automatic) on-site real-time operation of the algorithm. The collaboration with SOWINDIC allows SOPWICO to additionally benefit from SOWINDIC’s knowledge in the field of Machine Learning as well as to establish possible contacts for the real-time implementation of the algorithm. While SOWINDIC has access to data from only one wind farm, SOWINDIC on the other hand benefits from SOPWICO through a data exchange, which allows to test the developed algorithms more comprehensively.

Get in touch

Franziska Gerber

Meteotest AG

Project Manager Wind & Ice