Specialist insights and focal points

NOx reduction

The latest findings on the status of SNCR technology (selective non-catalytic reduction) as well as practical experience in the design and application of SCR (selective catalytic reduction) technology were presented. This applied both to the energy and industrial sector.

SO₂, SO₃ and dust emissions

Several contributions showed possibilities for further emission reduction, e.g. through targeted flue gas treatment or the optimisation of nozzle configurations in flue gas desulphurisation (FGD) scrubbers.

CO₂ separation – Preparation is everything

A central topic was the necessary pre-cleaning of flue gases before CO₂ separation by means of amine scrubbing. In particular, SO₃ and NOx must be efficiently removed in order to avoid amine degradation and undesirable side emissions such as monoethanolamine, nitrosamines and nitramines or ammonia. Cooling the flue gases to <40 °C is another technical challenge.

Heat recovery and condensation

The participants were particularly interested in options to recover heat from wet scrubbed flue gases through water condensation. By this technique, considerable amounts of energy (heat) can be recovered in combination with heat pumps. Successful large-scale applications have already been realised, particularly in the Nordic countries. This significantly improves thermal efficiency. The temperature regime in the flue gas achieved by heat recovery is also ideal for CO₂ capture.

PFAS emissions (perfluoroalkyl and polyfluoroalkyl substances) – A pressing issue

The problem of PFAS emissions from waste-to-energy plants (WtP) was addressed in an innovative contribution. A broad-based measurement campaign shed light on the release of these poorly degradable substances via ash, waste water and flue gases. The presentation impressively showed the far-reaching impact on both the environment and human organism.

First pilot plants for removing perfluoroalkyl and polyfluoroalkyl substances are already in operation. Initial results suggest that existing WtP plants contribute to the reduction of certain PFAS compounds. However, the work also showed that current detection methods are inadequate, highlighting the need to improve and harmonise protocols for reliable PFAS analysis.

Additionally, it turned out that technical solutions are important but fundamental rethinking is also required, i.e. the way humans deal with perfluoroalkyl and polyfluoroalkyl substances.

Conversion to 100 % biomass

Several contributions discussed the fuel switch of existing coal-fired power plants to pure biomass firing with corresponding adjustments to flue gas cleaning. This includes retrofitting of an FGD system and protecting the SCR catalytic converter from rapid deactivation.

Discussion and outlook

The contributions were discussed in depth. In a concluding discussion round, the future role of flue gas cleaning was critically analysed. There was consensus that the expected decommissioning of numerous coal-fired power plants would lead to a decline in the construction of new conventional flue gas cleaning plants. Nevertheless, flue gas cleaning remains essential for existing coal-, gas- and biomass-fuelled plants as well as waste incineration plants. It will also play a key role in the interaction with CO₂ capture technologies. Traditional flue gas cleaning and Carbon Capture and Storage (CCUS) are increasingly being viewed as integrated systems.

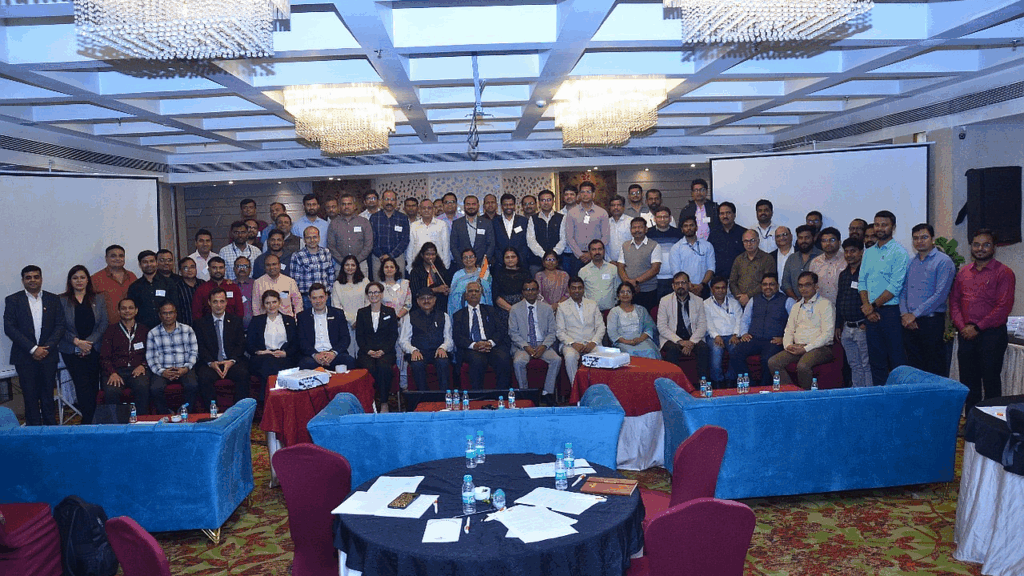

The dialogue among the participants was very constructive.

Besides, concrete operator solutions, including those from AS Latvenergo, which were presented alongside innovative technologies from service providers, deserve special mention.

Summary

The Flue Gas Cleaning Workshop 2025 was an all-round successful event with technical depth, new perspectives and a clear view of the challenges of the future. The close link between classic flue gas cleaning, CO₂ separation and new environmental requirements will continue to characterise the industry.

The vgbe team would like to thank all lecturers and participants who made a significant contribution to the success of the workshop.

We would also like to express our special thanks to AS Latvenergo for their kind support in organising the workshop and the impressive and very informative tour of the TEC-2 power plant.