The energetic utilisation of waste and sewage sludge as substitute fuel in conventional plants has been a tried and tested technology for years. Waste management thus makes a significant contribution to conserving resources and protecting the environment.

According to the Federal Statistical Office, a good 80 % (1.34 million tonnes) of sewage sludge from municipal sewage treatment plants in Germany was thermally recycled in 2022, i.e. 132.8 million kWh of electricity and 355.9 million kWh of heat were generated. The portion of sewage sludge utilised thermally has risen steadily in recent years. To improve resource utilisation, phosphorus recovery from sewage sludge will also become mandatory from 2029. According to the current state of the art, this recovery is mainly possible from the residues of thermal processes.

A large portion of non-recyclable residual waste is thermally treated in waste incineration plants, one of the main pillars of waste disposal in Germany, in order to generate electricity and heat.

In Germany, waste, biomass and sewage sludge are mainly thermally processed in grate firing and fluidised bed combustion plants. Both types of firing are roughly the same size and face similar challenges in terms of electricity generation, district heating or process steam extraction, flue gas cleaning, contamination and corrosion. Accordingly, the vgbe Conference “Thermal Waste/Sewage Sludge Treatment and Fluidised Bed Combustion 2023” was held for the second time in December 2023 to address these challenges of fuel conversion for power and heat generation.

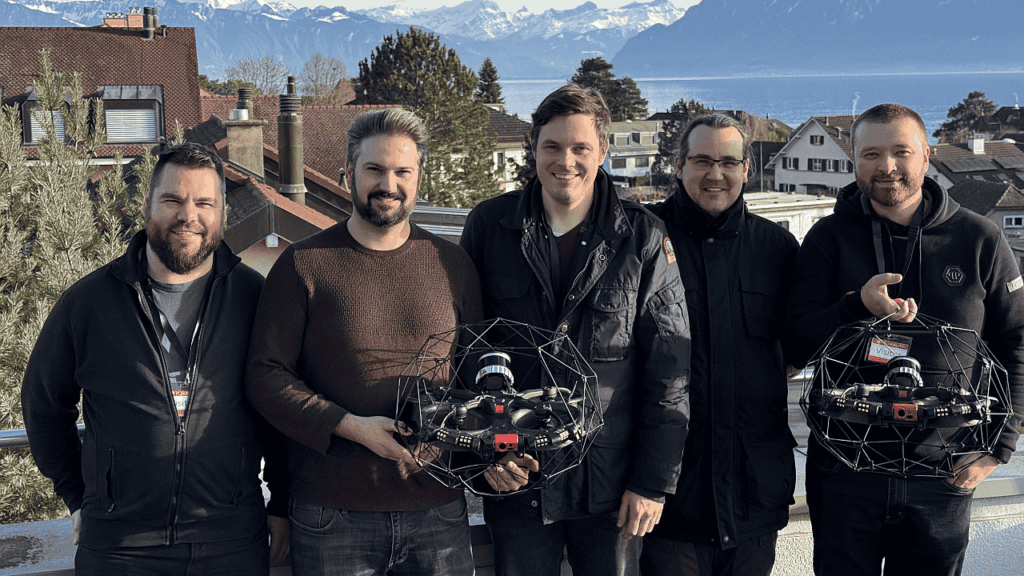

The approximately 140 participants were offered an interesting lecture programme, which was accompanied by a trade exhibition.

The conference focussed on the following topics:

- Fuel flexibility, fuel range, fuel availability and fuel treatment

- Contamination, slagging, corrosion and erosion

- Primary and secondary emission reduction (flue gas cleaning)

- Compliance with emission limits (including necessary process optimisation)

- Experience with operating and emission measurement systems

- Ash utilisation and phosphorus recycling

- Operating experience

- New plant construction and retrofitting

- Prospects for technologies in the context of EU climate protection legislation

- Process simulation

- Current research results

The contributions by Martin Pohl “Impact of national fuel emissions trading on waste management”, Harald Moosandl “Flue gas heat and exhaust steam heat utilisation”, Matthias Trost and Alexander Trost “Expansion joints in refractory linings – theory and practice” and Harald Hanßen “Thermal sewage sludge utilisation and P recycling in Hamburg” deserve special mention.

Martin Pohl presented in his paper the possibilities for continuously determining and monitoring CO2 emissions in waste gas streams. The method outlined, based on the fuel-specific parameter CO2,max, only requires the oxygen and carbon dioxide concentration in the flue gas to determine the biogenic CO2 content and can therefore be determined di rectly in the emission evaluation system.uswertesystem ermittelt werden.

Harald Moosandl presented the topic of “Flue gas heat and exhaust steam heat utilisation” in his lecture on the innovative use of industrial waste heat for feeding into the 600 km long district heating network of the city of Mannheim and the region. By the end of this decade, the district heating supply should be completely, i.e. 100 %, converted to green energy sources.

Matthias Trost and Alexander Trost demonstrated the necessity of maintaining expansion joints in refractory construction, such as in fluidised bed furnaces, with impressive examples and solutions. 70 % of damage to refractory linings is caused by expansion restriction, triggered by inadequate design, installation, operation and maintenance.

The construction and commissioning of the “Thermal sewage sludge utilisation and P-recycling in Hamburg” by Harald Hanßen dealt with the commissioning phase, which took significantly longer than expected, meaning that regular operation cannot commence until the first quarter of 2024. The process concept has proven itself. Phosphoric acid is currently produced discontinuously with a degree of purity that enables marketing of the highly demanded phosphoric acid.

The first day of the conference ended with a joint evening event. Here, speakers, participants and the exhibiting companies had ample opportunity for professional dialogue and networking.

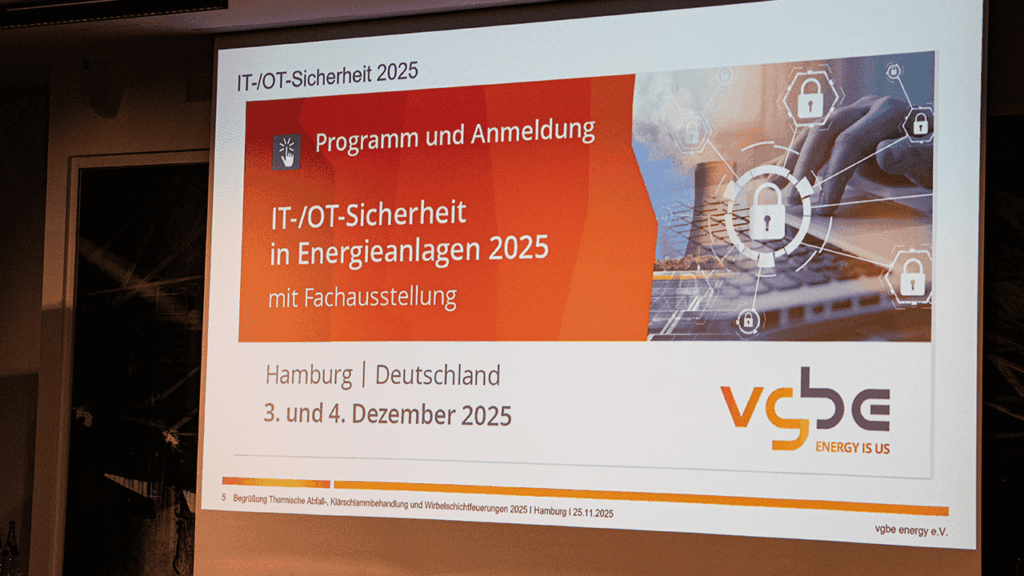

The second day of the event was to be rounded off with a technical tour of the phosphorus recycling plant at the Hamburg sewage sludge treatment plant. Unfortunately, this visit could not take place for technical reasons and will be repeated at the next conference in December 2025.

Phosphorus is a finite but vital raw material that Germany already has to import almost entirely. Waste water is a valuable source of phosphorus – this potential is being utilised in an impressive way by Hamburger Phosphorrecyclinggesellschaft mbH with the operation of the world’s first large-scale plant for the recovery of this important raw material.

The vgbe event team would like to thank all participants, speakers and exhibitors for their valuable contributions, exciting discussions and insights into the portfolio of the exhibiting companies.

The next vgbe Conference “Thermal Waste/Sewage Sludge Treatment and Fluidised Bed Combustion 2025” will again take place in Hamburg in December 2025. The date will be announced in good time on the vgbe website and in the vgbe energy journal.