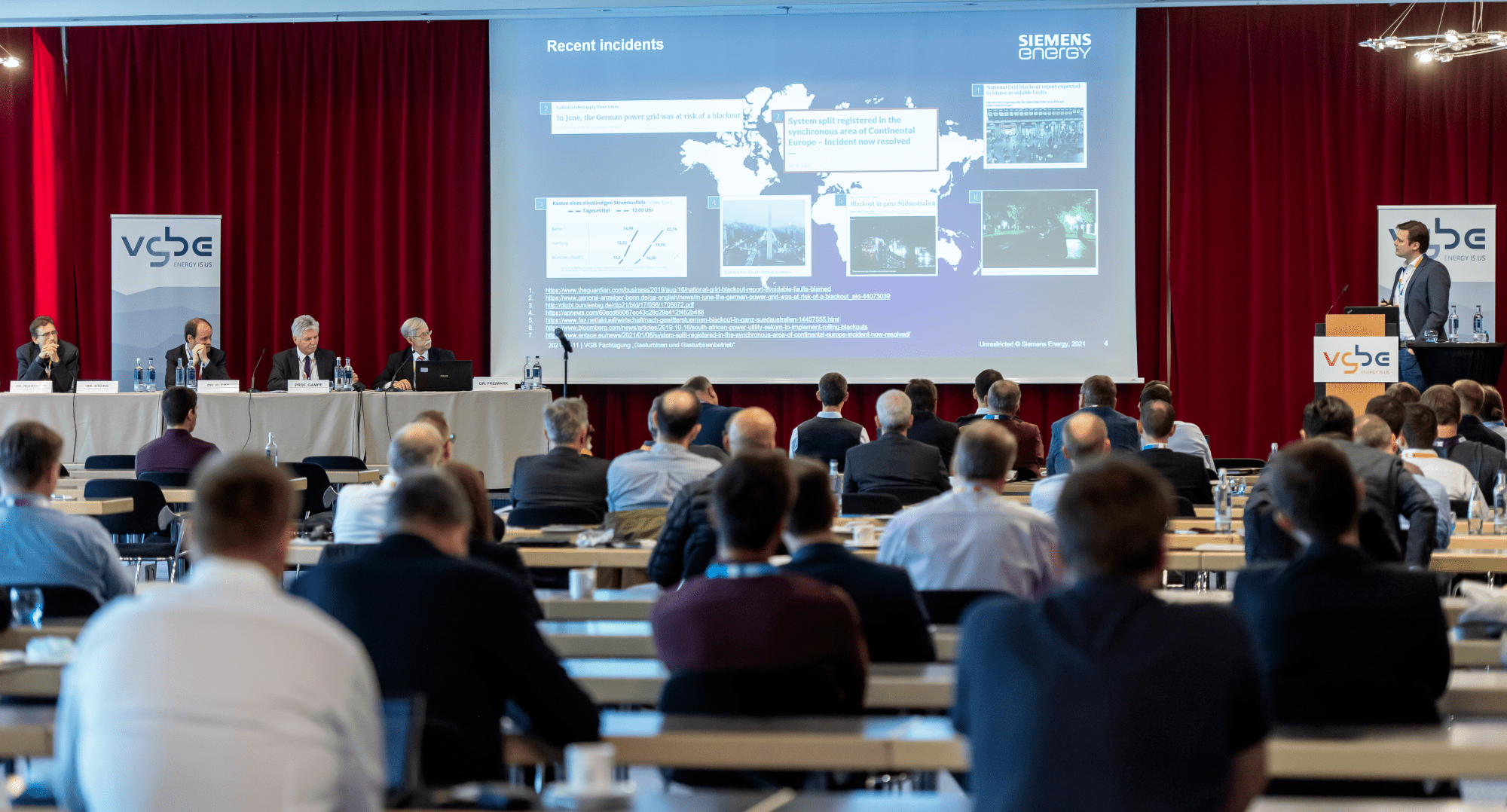

The vgbe conference on gas turbines and gas turbine operation took place on 11 and 12 November 2021 at the Dorint Hotel in Potsdam in compliance with the valid Corona hygiene measures. Around 150 participants from Germany and other European countries had the opportunity to inform themselves and discuss current gas turbine trends. In addition, the accompanying trade exhibition with 20 exhibitors offered numerous opportunities for professional and personal exchange outside the lecture hall.

Of the 16 top-class contributions, five lectures should be mentioned first, in which the focus was on future hydrogen-based power generation. From the fundamental problems of building a hydrogen economy that is as green as possible to the development of hydrogen-fired turbines and the necessary retrofitting of the existing gas turbine park, the topic was discussed from different aspects. All contributions made clear that this is a complex project for all parties involved. It is not expected that the re-electrification of hydrogen in the power industry will be implemented on a large scale in this decade due to the current cost situation. However, work is being carried out at full speed on readiness for application and the modification of existing turbine systems in order to meet the increasing requirements for a decarbonised energy supply. Gas turbines are also gaining in importance in terms of their controllability, which is available to cover the residual load in the further expansion of volatile renewables, regardless of weather conditions.

Dr Karsten Klemp, RheinEnergie AG

From the point of view of a regional utility, the transformation to CO2-free electricity and heat supply with synthetic gases – preferably based on renewables (green hydrogen) – was presented. In the field of gas turbines, this means fuel switching or co-combustion of hydrogen in existing gas turbine plants, which are predestined for the fuel switch from fossil natural gas to hydrogen. In this context, the low-pollution micro-mix combustion in gas turbines was discussed.

In this process, gas turbines reconvert electrical energy and heat without any CO2 emissions. Fuel-flexible gas turbines are considered a bridging technology towards a hydrogen-based energy supply and have the potential to significantly reduce the CO2 emissions of the energy industry. However, this requires the adaptation of existing turbines designed for natural gas. This was discussed using the development and practical examples of dry-low NOx combustion chamber technology as an example. The necessary modifications of the gas turbine combustion chamber for using hydrogen and hydrogen-rich gases, the potential of nitrogen oxide reduction and the influences on turbine control were described. Micro-mix combustion has already been successfully operated and tested with 100% hydrogen input.

In another contribution, the problem of co-combustion of hydrogen in an existing turbine was addressed. Several challenges arise, such as flashback, increased NOx emissions due to locally higher temperatures during hydrogen co-combustion, H2 delivery and mixing with natural gas and safety aspects of handling hydrogen on site.

In addition to the use of hydrogen and hydrogen mixtures in gas turbines, the 11 other contributions reflected on the state of the art of gas turbines. For example, one paper presented the innovative production of a turbine inlet blade with a novel cooling system using LPBF (laser powder bed fusion) technology.

The production of the turbine blade in the 3D printer offers a unique opportunity to modernise even older gas turbines in an economical and environmentally friendly way. The fundamental requirements for the new entry blade were, in addition to improving economic efficiency and future-proofing, life cycle costs, spare parts supply, nitrogen oxide emissions and optimising turbine efficiency and performance. After defining the target parameters, it was possible to save cooling air while maintaining a robust design without reducing service life. . The cooling air savings should reduce nitrogen oxide emissions and increase turbine efficiency in line with the turbine’s operating mode. The newly manufactured blade is currently being validated at a site in commercial operation.

Other interesting presentations dealt, among other things, with the amendment to the 13th BImSchV and the associated emission reduction requirements for gas turbines and the possible effects on the existing and future gas turbine fleet in Germany.

Contributions on increasing the availability and plant safety of gas-fired power plants through simulator training, the modernisation of a CHP plant with a newly developed gas turbine and the latest trends in condition monitoring, including state-of-the-art vibration diagnosis, rounded off the interesting lecture programme.

In addition to the presentations and the lively discussions that followed, the participants took the opportunity to network and exchange ideas. Similar to previous vgbe attendance events, it was clearly noticeable that the aspect of personal contact was very much appreciated and that the participants were very positive about direct communication. In the meantime, accelerated by the pandemic, there are proven and successful remote and hybrid event formats as an alternative to face-to-face events, but the personal exchange on the sidelines of the event and at the joint evening event still cannot be replaced by digital conferences. At this year’s gas turbine conference, there was once again ample opportunity for personal discussion. In addition to the already mentioned, exceptionally well-attended trade exhibition, the participants and exhibitors were able to round off the first day of the conference in a pleasant atmosphere at the joint dinner on the evening of the first day of the event.

The vgbe conference team would like to thank all participants, speakers and exhibitors for their visit and their contribution to the gas turbine conference and is looking forward to the next vgbe gas turbine conference, which will take place in Koblenz from 6 to 7 June 2023. Information will be given in due time on the vgbe event portal and in the VGB POWERTECH Journal.

For more information, please visit the new vgbe event platform!