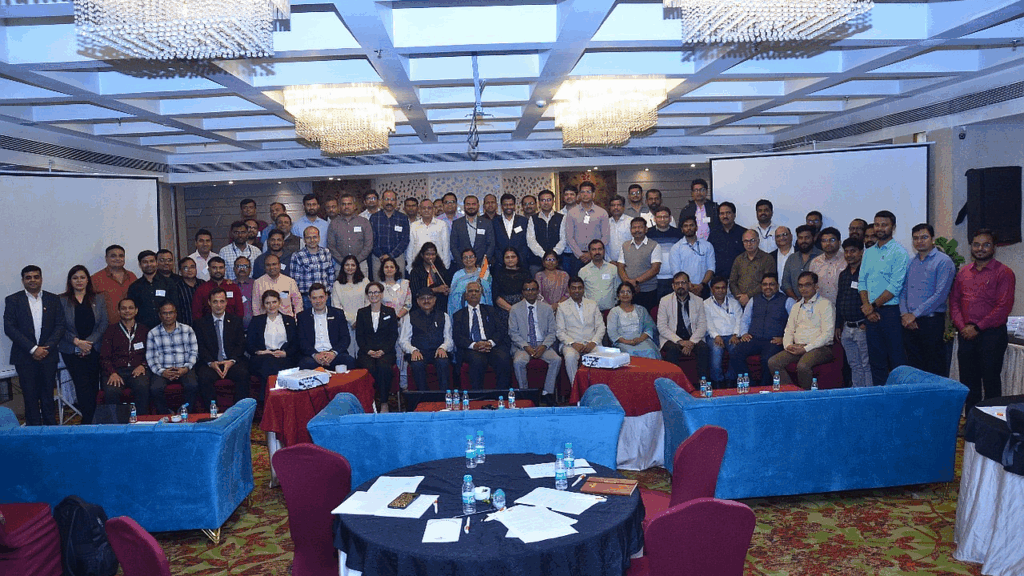

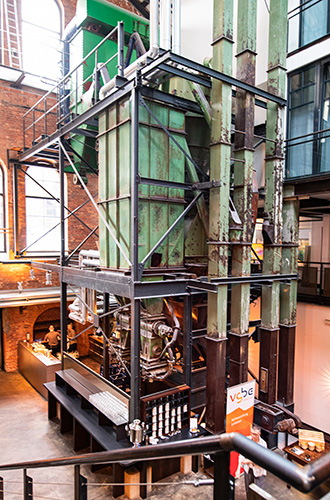

On 25 November 2025, approximately 150 participants from Germany, Austria and Switzerland gathered at the former gasworks site, which had played a central role in Hamburg’s energy supply from its commissioning in 1896 until the 1960s. Following its impressive transformation into a listed design hotel featuring exposed piping systems and steel structures, the venue provided a distinctive industrial atmosphere from the outset.

After the official welcome by Dr Thomas Eck and conference coordinator Verena Quiskamp (both vgbe energy e.V.) in the main conference hall, Peter Knapp (MVV Energie AG) and Dr Yves Noël (RheinEnergie AG) chaired the event as moderators and section leaders. A total of 16 presentations were delivered across five thematic sections:

- Regulatory developments

Presentations covered, among other topics, current developments in emissions trading, amendments to Germany’s Federal Immission Control legislation (BImSchV), and practical issues relating to regulatory enforcement. - Flue gas and process off-gas streams

Topics included phosphorus recovery, flue gas cleaning and CO₂ capture technologies, corrosion phenomena and potential countermeasures. - Artificial intelligence and digitalisation

This section focused on intelligent internal inspections, optical condition monitoring using drones, and the AI-supported detection of hazardous objects in combustion plants. - Refractories

Presentations addressed the application of the finite element method, refractory performance in grate-fired systems, and calorific-value-based fuel control in fluidised bed combustion. - Operational experience

Contributions included reports on the construction and operation of the Hannover-Lahe sewage sludge incineration plant, as well as the construction of the Hamburg-Stapelfeld waste-to-energy facility.

- Regulatory developments

To provide insight into the technical depth of the conference, several presentations are highlighted below.

Marie Kaiser, CheMin GmbH: Causes of sulphuric and hydrochloric acid corrosion and potential countermeasures

Corrosion in the cold-end section of a plant is typically associated with local accumulations of specific salts or acids. As new processes increasingly operate at lower temperature levels, this issue is gaining relevance. In her presentation, Marie Kaiser provided a clear and comprehensive introduction to the topic, illustrating typical damage patterns and their causes using practical examples and her own investigation results. Potential mitigation measures were also discussed, including specialised coatings, the use of corrosion-resistant materials and design-related adaptations.

Markus Rost, Constructure GmbH: Optical condition monitoring of a masonry chimney using drones and AI-based image analysis

Susanne Kumm, InspecDron GmbH: Intelligent internal inspection in waste-to-energy plants

For the inspection of very tall or difficult-to-access structures, where conventional testing involves significant cost, drone-based inspections have for several years offered an effective and cost-efficient alternative in outage planning and maintenance. More recently, AI-based automated systems for detecting damage patterns have been introduced. By eliminating the need for costly scaffolding and temporary containment structures, both financial and human resources can be conserved. A key conclusion shared by both speakers was that effective inspection concepts require a combination of IT systems, artificial intelligence and engineering expertise.

Mareike Weidemann, enercity contracting: What to consider when planning or constructing a sewage sludge treatment plant

The presentation by Mareike Weidemann generated particularly strong reactions from the audience. Combining dry humour with professional authority, the experienced division manager delivered an engaging and highly illustrative talk. Using striking images and clearly worded key messages, she highlighted the challenges and failures encountered during the construction and commissioning of the Hannover-Lahe sewage sludge incineration plant.

By the reference date of 30 September 2025, a total of 250,000 tonnes of sewage sludge had been incinerated at the plant, producing approximately 96,000 MWh of district heating. However, the first two years of operation were also characterised by technical challenges, resulting in around 5,500 hours of unplanned downtime. Weidemann’s willingness to openly share these experiences in order to support future projects in the industry was met with strong applause and lively discussion.

Exhibition, networking and evening event at the Gastwerk Hotel

There was ample opportunity for professional exchange on waste utilisation and combustion technologies, resulting in lively discussions between plant operators, service providers and long-standing industry contacts. Dr Thomas Eck commented: “There was an exceptionally open and welcoming atmosphere. Participants were able to engage in in-depth technical discussions over excellent food and to meet the exhibitors during the breaks.”

With twelve sponsors and exhibitors, the conference featured a particularly broad range of product and service presentations. Participating companies included CMV Systems, Explosion Power, iqony, J+G Refractories, KWS, Martin, Meeraner, Online Cleaning Technologies, OptiOil, Power Service Solutions, Turbonik and WasteAnt.

From theory to practice: site visits in Hamburg

The final highlight following two intensive conference days was a guided visit to two operational facilities: the Hamburg-Stapelfeld waste-to-energy plant, which had been presented during the closing lecture, and the Vera I and II sewage sludge treatment plants. Commenting on the site visits, vgbe representative Verena Quiskamp noted: “Organised plant tours of this kind are rare and therefore highly valued. They offer an excellent opportunity to discuss practical issues directly on site and to gain insight into the daily work of colleagues across the industry.”

The conference as a whole – including technical sessions, the evening event and plant visits – was highly successful. The vgbe team would like to thank all speakers, participants and exhibiting companies for their valuable contributions and the open, constructive discussions that significantly contributed to the success of the event. Details of the next conference, expected to take place in approximately two years, will be announced in due course via vgbe Event Calendar and LinkedIn.