This year, the traditional vgbe Chemistry Conference celebrated its 60th anniversary. From October 22 to 24, 2024, approximately 160 participants from Germany and abroad gathered in Potsdam to discuss and learn about the latest trends and challenges in power plant chemistry.

The first day centered on water treatment and its effects on the water-steam cycle. Various membrane technologies were presented and compared with traditional ion exchangers. In particular, the contributions by Christoph Maurer and Dheneshree Lalla et al. stood out.

In his presentation, “Efficiency-Enhancing Measures in Water Treatment,” Christoph Maurer demonstrated how critical water constituents such as dissolved organic carbon (DOC) and silicates can be effectively retained using membrane technology. He highlighted the benefits of combining membrane technology with ion exchangers, creating a synergistic approach for optimal utilisation. Numerous practical examples illustrated how this method enables ecological and economical use of water – a scarce and valuable resource increasingly affected by climate change.

In her presentation, “ Utilisation of membrane technology processes (desalination plants) for demineralised water production in power generation – the ESKOM experience,” Dheneshree Lalla detailed how the South African operator employed membrane-based systems at two power plant sites to produce demineralised water. Her presentation emphasised the importance of feedwater quality and provided an in-depth explanation of the reasons for selecting membrane technology over ion exchangers.

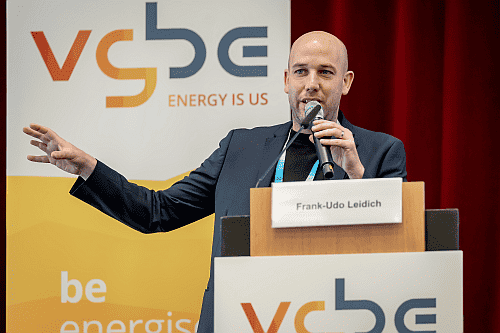

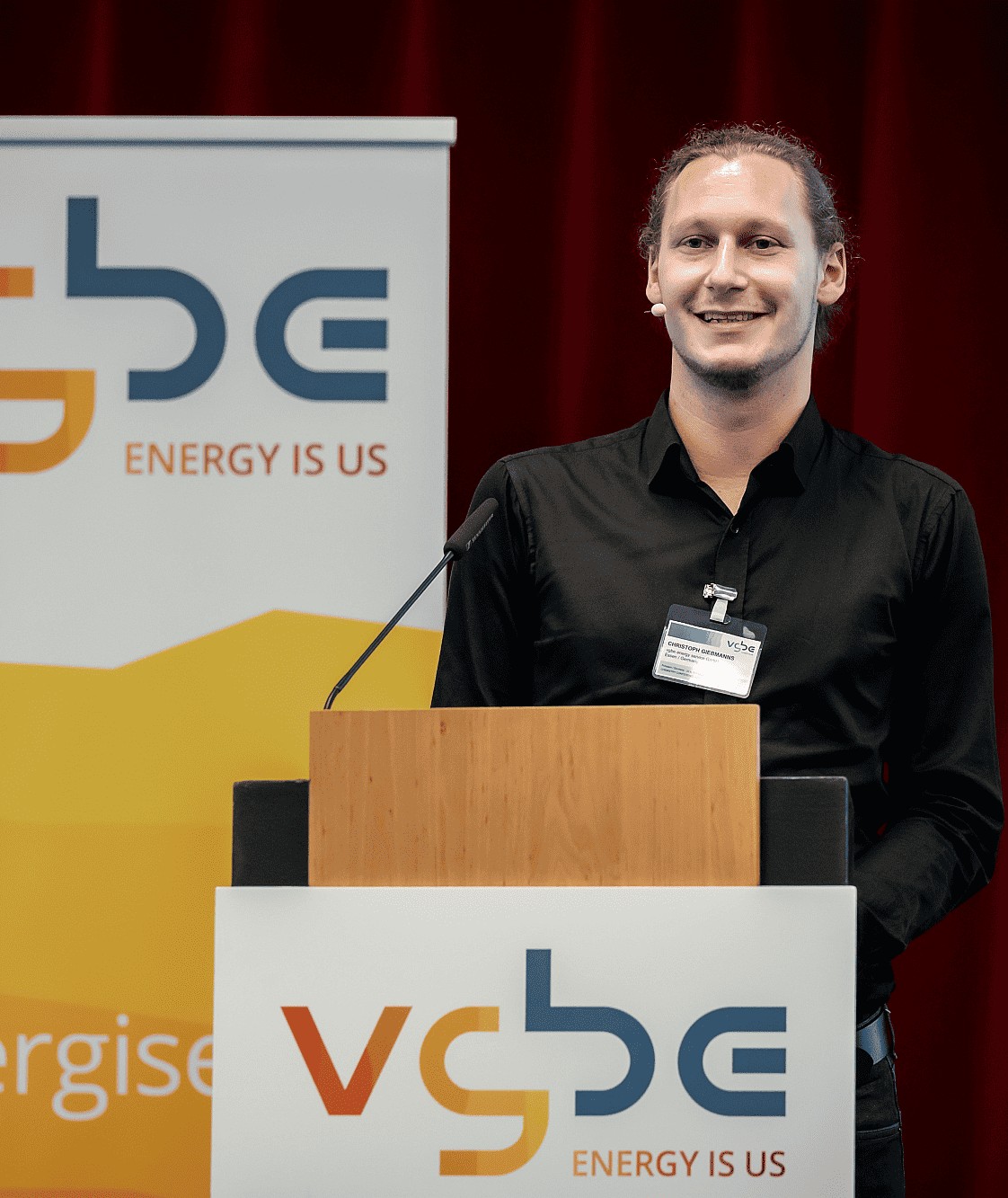

Another highlight was Christoph Giebmanns’ presentation, “Practical examples: turbine salinization – An old topic, but always relevant.” As head of water chemistry at vgbe Technical Services, he emphasised the significance of monitoring working mediums for trouble-free operation and addressed potential steam turbine damage from deposits and corrosion. Should such damage occur, cleaning methods for steam and gas turbines are available, as described by Frank Udo Leidich in his paper, “Foam cleaning of steam and gas turbines.” He outlined effective non-invasive cleaning methods that avoid dismantling turbines, preventing efficiency losses and further damage.

The second day of the conference addressed the growing need for flexibility in conventional plants due to increased renewable energy generation. The focus was on the impact of flexible operation on power plant chemistry. Michael Rziha’s presentation, “Typical and frequent chemical problems in plants with cyclical operation,” garnered significant interest.

He described cyclical operation – characterised by frequent load changes, numerous shutdowns, and repeated startups – as the new normal. Michael Rziha shared valuable insights on how to detect critical effects using measurement technology and implement timely countermeasures.

Zanele Dladla explored a similar theme in her presentation, “Impact of low-load operation on cycle chemistry – Eskom experience and perspective at two coal-fired power stations”. She shared investigation results that revealed how low-load operation affects power plant chemistry at two subcritical (>16 MPa boiler) coal-fired power plants. These findings, consistent with international experience, highlighted the challenges of maintaining cycle chemistry control under such conditions.

Monika Nielson’s presentation, “Water chemistry in clectrode boilers – Experience from Ørsted in Denmark,” provided an interesting case study. At Ørsted’s Studstrup site, six high-voltage electrode boilers (2 x 40 MW and 4 x 50 MW) are used for district heating and as a fast frequency reserve (FFR) in the Nordic synchronous area. Nielson discussed operational challenges, including sparking, pH drops, electrode corrosion, and issues with H2 and O2 formation, as well as TOC and SiO2 contamination. These problems arose from differences in water chemistry treatments, such as conditioning with NaOH versus Na3PO4.

A new addition to the conference was a panel discussion addressing current and future topics in power plant chemistry. Topics included carbon capture and utilisation (CCSU), the transition from large boilers to smaller plants, hydrogen economy market ramp-up, and electrolysis water quality for hydrogen (H2) production.

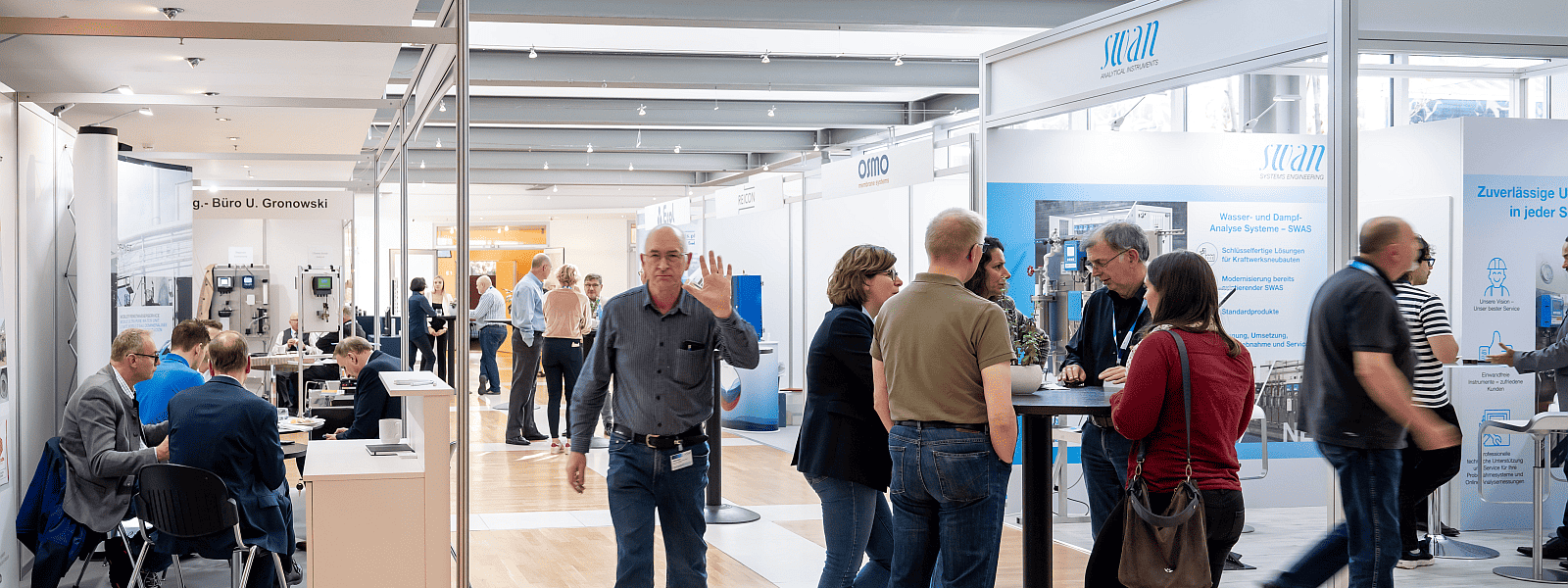

As per tradition, the conference featured a trade exhibition, where 19 exhibitors showcased their products and services. This exhibition, alongside the evening networking events, is a key component of the vgbe Chemistry Conference. These events foster valuable interactions among visitors, exhibitors, and speakers.

This year’s networking activities were generously sponsored by Swan Systems Engineering (get-together), Kurita Europe GmbH and Purolite GmbH (evening event). vgbe extends its heartfelt thanks to these sponsors for their support. The vgbe Chemistry Conference team expresses its gratitude to all participants, speakers and exhibitors for their contributions, which made this event a success.

The vgbe team is already looking forward to the next vgbe Chemistry Conference, scheduled to take place in Kassel from October 28 to 30, 2025.