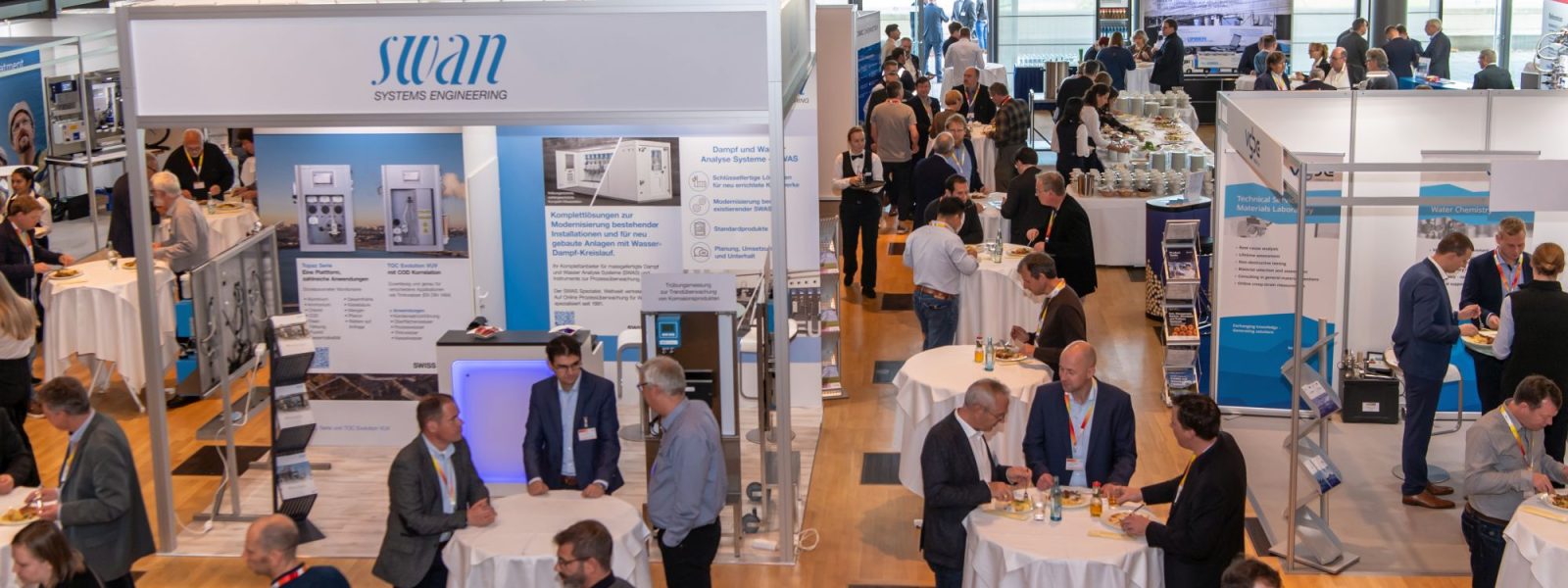

This year, the vgbe Chemistry Conference took place for the 58th time from 25 to 27 October 2022 in Dresden with around 170 participants from Germany and abroad. As in previous years, this year’s event was again accompanied by an informative trade exhibition where 18 exhibitors presented their products and services.

After the opening, the event initially focused on the vgbe rules. The vgbe Standards reflect the state of the art for the generation and storage of electricity and heat. Especially in the field of power plant chemistry, vgbe has published a number of internationally recognised standards over the past decades. These include the vgbe Standard S-010 “Feedwater, Boiler Water and Steam Quality for Power Plants/Industrial Power Plants” and the “Cooling Water Guideline” VGB-R455P. In two lectures, Michael Rzhia, who was significantly involved in both revisions, reported about the revision, respectively the transfer of the VGB Guideline VGB-R455P into a vgbe Standard.

The vgbe Standard S-010 was introduced in 2011 revising the former “VGB Guideline 450 for Feedwater, Boiler Water and Steam Quality for Power Plants/Industrial Plants”. The vgbe-S-010 represents the sum of accumulated experience from power plant chemistry and covers all pressure ranges encountered in boilers for the generation of heat, steam and/or electricity. Over the past 11 years, this Standard has become established and acknowledged. However, in 2020 it was agreed to revise this vgbe Standard to take into account the latest technical developments and challenges, such as cyclic plant operation, the increased use of amine-based conditioning chemicals, and other design features of CCGT plants, etc.

In the presentation, the status of the revision was presented: an international working group has identified 80 individual topics that are to be revised, rewritten for further specification or also integrated as new information. The revision is now largely complete, so that publication can be expected in the near future.

In his second presentation on vgbe rules and regulations, Michael Rziha reported on the revision of the VGB Cooling Water Guideline VGB-R 455, which is now being transferred into a new vgbe Standard – vgbe-S-455. This guideline was published in 2000 to replace the 1990 edition. Since 2010, several attempts have been made to revise it, but these had to be repeatedly interrupted, including completion of the 42nd BImSchV and VDI 2047 (“Legionella”), which had been waited for because these were to be incorporated. Since May 2021, a newly established working group has now rapidly revised the Standard, and publication can also be expected soon. Compared to the previous Guideline VGB-R 455, the vgbe-S-455 covers more aspects about cooling water systems, cooling water treatment, materials and other relevant topics. Furthermore, the standard does not only focus on power plants, but also covers the operation and characteristics of other industrial cooling systems such as waste and biomass incineration plants, steel plants, refineries, the chemical industry, etc. As far as reasonable and possible, not only German but also European as well as international standards and regulations have been taken into account.

The entire lecture programme comprised a total of 24 contributions. Among others, the presentation by Nana Mattiß “Iron problems in the water-steam cycle” should be mentioned. Repeated quality problems in the water of a CCGT plant newly constructed in 2019 have been observed since commissioning, although a condensate polishing system (mechanical and physical) has been in use. The impurities have been visible through contamination on the sampling system. In 2021, a turbidimeter was employed. Several dependencies between conditioning and oxygen input could be clearly demonstrated.

Furthermore, the effects of a rather short-term (of only a few minutes) operation with “bad parameters” were very surprising and the basic “side process” could be identified as the culprit.

This problem was also addressed in a contribution by Lars Dittmar. In the paper “Behaviour and effects of corrosion products in plants with frequent start-up processes and their monitoring – Turbidity measurement as trend monitor for particulate corrosion products”, the difficulties of online analysis for the detection of iron and other corrosion products were explained. Usually, these analyses are carried out in the laboratory at great expense of time. However, online analysis is increasingly necessary and in demand. In addition to the theoretical basics, the lecture also presented the possibilities of using ISO 7027-compliant turbidimeters for continuous trend analysis of corrosion products in power plant operation and pointed out their limitations.

Efficiency enhancements are always part of the continuous improvement process in any technical process. In the paper “Kurita Dropwise technology as efficiency improver in power plant condensers”, André de Bache has presented how heat transfer can be improved. The steam generated in industrial boiler plants is usually condensed as water film, e.g., in heat exchangers, condensers, dry cylinders, etc., depending on the intended use of the steam generated. Der so entstandene dünne Kondensatfilm wirkt wie ein Isolator, der die Wärmeleitung im Produktionsprozess erheblich behindert. The resulting thin film of condensate acts like an insulator which considerably impedes heat conduction in the production process.

It was shown how the liquid film of condensed water on metal surfaces can be reduced by applying the “Kurita Dropwise Technology” based on film-forming substances. In this process, hydrophobic surface conditions are created shifting the film-like condensation to dropwise condensation so that heat transfer efficiency is increased.

Supply bottlenecks, which are now affecting the entire industry, do not stop at power plant operations and pose particular challenges for power plant chemists. Accordingly, this topic was intensively discussed at this year’s vgbe Chemistry Conference. A change from hydrochloric acid to sulphuric acid with the corresponding disadvantages was discussed and the use of mobile reverse osmosis plants was also considered. However, supply bottlenecks are also arising.

Anne Wiesel’s contribution impressively demonstrated that knowledge about chemical processes in the scrubber sector is available and can be used. In her presentation “Increased nitrate concentration in the FGD wastewater of a hard coal-fired power plant”, the question was posed as to what unforeseen surprises a changed of coal might bring? In addition to supply bottlenecks, the use of coal of different provenance, for example, is one of the challenges of current energy supply. In the present case, the use of low-sulphur hard coal and the observed increase in nitrate concentration in the FGD wastewater were described. In order to understand the cause-effect principle and to eliminate the cause as quickly as possible, a deep dive into the reaction equations of FGD chemistry is necessary and knowledge from the 1990s, which was developed in particular by the working group around Prof. Gutberlet, can be used. Anne Wiesel provided an explanatory approach without complete and elaborate analysis of the FGD processes.

Following the lectures, there was ample room for discussions, which had already begun at the get-together on the evening before the event and continued at the evening event on the first day of the conference. The “vgbe family reunion of power plant chemists”, as this traditional vgbe conference can well be described, has once again shown the value of personal contact and networking among power plant chemists. This event format creates the necessary framework to broadly discuss and analyse current trends.

The vgbe conference team would like to thank its sponsors Swan Analytical Instruments AG, Kurita Europe GmbH and Purolite GmbH as well as all participants, speakers and exhibitors for their valuable contribution to this successful event.

The vgbe team is looking forward to another “family reunion” in 2023 at the 59th Chemistry Conference, which will take place from 24 to 26 October 2023 at the Maritim Hotel in Ingolstadt.