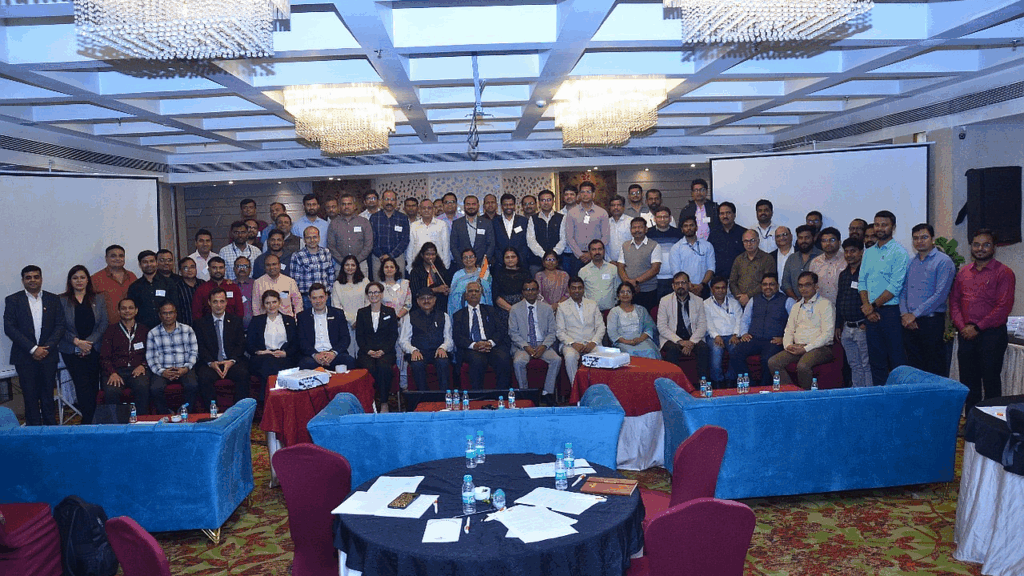

These complex topics were the focus of this year’s vgbe Conference “Cooling Systems 2025”. Around 90 participants took the opportunity to exchange ideas on current trends and challenges within four sections:

- Plant and system technology:

Fundamental aspects of the design and operation of various cooling systems - Water treatment in open and closed cooling systems:

New concepts for cooling water treatment, focusing especially on minimising the use of biocides and the targeted application of microorganisms - Operation and maintenance:

Cleaning and operational monitoring of evaporative cooling systems, heat exchangers and fans, including the use of “digital twin” technologies - Regulatory requirements and guidelines:

Noise emissions as well as German and European technical regulations and legislation

- Plant and system technology:

The high-quality programme covered a broad range of subjects, from air coolers used as heat sources for industrial heat pumps, through challenges in cooling water management such as legionella prevention and mussel fouling, to the design and operation of components like pumps and fans, as well as regulatory requirements from the German 42nd BImSchV to the European BREF ICS.

Highlights from selected presentations

Design aspects of evaporative cooling systems

In his presentation “Design aspects of evaporative cooling systems for optimal operation at full and part load”, Manfred Roth outlined the key principles of cooling tower design. When planning a cooling system, the entire process has to be considered to avoid unnecessary oversizing. The selected design point determines the required driving energy for pumps and fans. Significant energy savings can be achieved by using frequency-controlled drives and well-designed control systems, especially in systems with multiple cooling cells.

Selection and operation of pumps

Energy efficiency was also the focus of Bernhard Koritsch’s presentation “Selection and operation of pumps”. He presented different designs of cooling water pumps and explained criteria for optimal system layout as well as the influence of operating points, load profiles, and operating modes on efficiency and wear. Practical examples demonstrated that in complex pumping systems, energy savings of over 60% can be achieved through demand-oriented operation, reduced pressure losses, intelligent pump control and timely maintenance.

Dry coolers as heat sources for heat pumps

In his contribution “Structure and function of dry coolers and their use as heat sources for industrial heat pumps”, Ulf Bergmann explained how dry coolers cannot only dissipate residual heat in industrial, air-conditioning and refrigeration systems, but also serve as efficient heat sources for industrial heat pump systems. This application, however, requires specific modifications in design and operation, which were discussed in the presentation. Reference projects on an industrial scale, mainly from Scandinavia, were also presented.

Noise emissions and low-frequency noise in cooling tower construction

In the section “Regulatory requirements and guidelines”, Thomas Meyer addressed “The challenge of low-frequency noise in cooling tower construction – generation, mitigation, and limitations”. His paper highlighted the acoustic challenges of large-scale cooling towers, emphasizing that particularly low-frequency emissions below 100 Hz can propagate over long distances with little attenuation, potentially disturbing nearby residents. Currently, there are no clear limits or binding standards for assessing such emissions. Therefore, it is essential to integrate noise control measures early in the design phase. Thomas Meyer discussed the main causes of low-frequency noise and evaluated existing mitigation options regarding effectiveness, feasibility and practical implementation.

Exhibition and networking

In parallel with the conference, nine exhibiting companies presented their products and services. Short company presentations before the first lunch break provided additional visibility and were very well received by participants.

Networking was another major aspect of the event: participants exchanged ideas during breaks, exhibition, lunch and evening event. Discussions focused on energy and water savings, new developments in water treatment to reduce biocide use and the targeted use of microorganisms for cleaning cooling water circuits.

Conclusion

The third vgbe Conference “Cooling Systems” was once again a great success. It covered the entire range of industrial cooling from plant and system technology to water treatment, operation, maintenance and regulatory frameworks.

The vgbe team extends its sincere thanks to all speakers, participants and exhibiting companies for their valuable contributions and open, constructive discussions, which were instrumental in making the event a success.

The next “Cooling Systems” conference will take place in 2027, with a two-day workshop planned for 2026. Dates and venues will be announced in due time through the usual vgbe channels.