The Technical Programme “Material Safety in the Hydrogen Economy” has got off to a successful start and has developed very positively since the Steering Committee was formed around six months ago. Over the past six months, intensive work has been carried out on the content and structure of the project.

Two new partners have been acquired: Everllence (formerly MAN Energy Solutions) and TÜV Rheinland. As a result, the number of participating organisations has risen to ten. The participants currently include: RWE, Siemens Energy, Uniper, Fraunhofer IWM, CEZ, LEAG, Deloro Wear Solutions GmbH, Onyx Power, vgbe service GmbH, Everllence and TÜV Rheinland.

As already communicated, Fabian Unterumsberger (RWE) is the Chairman of the Steering Committee, while Jens Ganswind-Eyberg is the responsible consultant for vgbe.

In five meetings of the Steering Committee, the programme priorities were sharpened and an initial project list defined. In line with the programme’s focus, issues relating to the safety and reliability of materials in hydrogen technology applications are on the agenda. The prioritised topics include

Material behaviour in hydrogen environment

- Temperature-dependent sensitivity windows

- Diffusion and embrittlement due to hydrogen in various materials

- Hydrogen embrittlement in cold-formed austenitic steels (9 % – 11 % Ni)

- Material selection for specific applications

- Qualification methods for strength classes for pipe materials

Non-destructive testing (NDT)

- Methods for detecting hydrogen-induced cracks

- Early detection methods for hydrogen embrittlement

Material selection under flexible operating conditions (frequent start-up and shutdown)

Special projects in the field of gas turbines

Exchange and cooperation with the vgbe Technical Committee “Gas Turbines and Gas Turbine Operation” is planned.

Coatings for hydrogen applications

- Armouring and wear protection solutions

Lifetime monitoring of membranes

- Optimisation of test and maintenance cycles

- Focus on electrolysers and fuel cells (AEL, PEM, AEM), reverse osmosis and membrane compressors

- Goal: Minimising membrane degradation and maximising service life through defined process parameters

The detailed project descriptions, including the scope of services, are currently being finalised – details are to be available by late summer 2025.

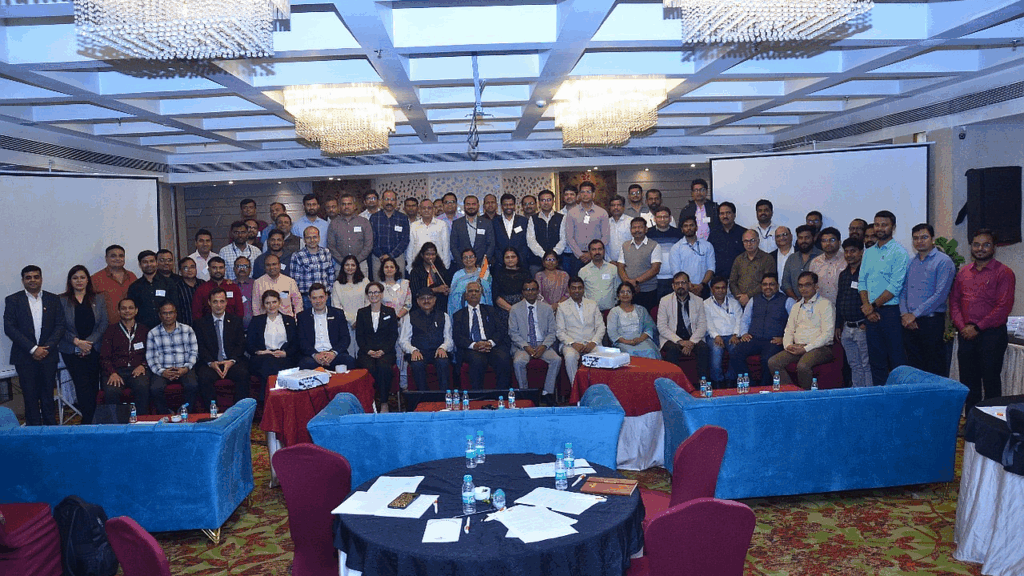

In addition to the project work, the meetings are also used for open professional exchange, including on standardisation issues, relevant specialist events and other current developments. As with all vgbe activities, networking plays a central role in promoting close cooperation between the partner organisations involved.

Background to the vgbe Technical Programmes

vgbe Technical Programmes offer a flexible, project-oriented framework for working on overarching or innovative topics outside of the traditional vgbe committee work. Participation is independent of vgbe membership and is possible at any time.